Welcome to the Society of American Period Furniture Makers

Dedicated to craftsmanship and fine furniture making education for over 20 years.

Visit the Phil Lowe Library where you can download scans of furniture pieces built by him.

Visit the Phil Lowe Library where you can download scans of furniture pieces built by him.

Save The Dates

June 28 - July 1, 2024

SAPFM Presents:

Period Furniture Construction, Conservation,

and History Conference

June 28 - July 1, 2024 - Collegeville, PA

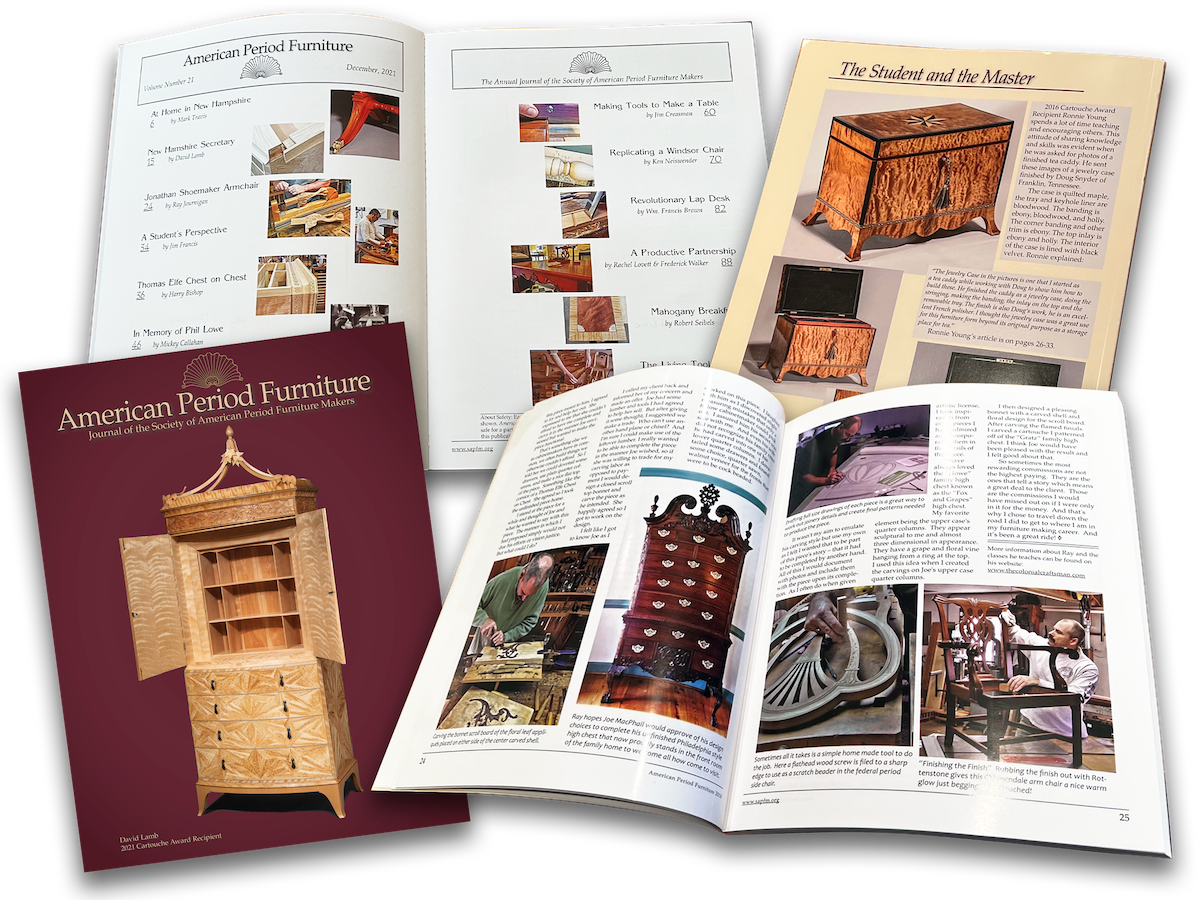

For more than 20 years, The Society of American Period Furniture Makers has been committed to providing our members with the best in fine furniture making education. We provide this service through our symposiums, publications, chapter meetings, and on-line resources.

We are a niche interest in the overall makers movement ...

Our Mission is:

☑ To create a forum for the understanding, education, and appreciation of American period furniture.

☑ To develop and encourage the use of standards and ethical practices in the reproduction and conservation of period furniture.

☑ To offer membership to all with an interest in period furniture.

☑ To assist members with the identification and location of resources including people or organizations having specialized expertise.

☑ To conduct public exhibitions for the recognition of members’ work.

SAPFM is here for you. We are dedicated to fine period furniture craftsmanship. Membership provides an opportunity to meet like-minded furniture makers, share information, and expand appreciation and abilities in making furniture. Collectors, enthusiasts, and academics have an opportunity to learn how furniture was made, how skills were acquired, how materials were used, and construction process and procedures.